Production machines are not exactly disposable items. They’re meant to last a long time. Decades, preferably. But with today’s rapid technological changes, it’s not hard to understand that these machines quickly “grow old”. After a few years, the technology is already outdated. The machine itself still works fine, but the technology inside the machine has disadvantages compared to today’s high-tech. Especially in terms of efficiency, operability and quality. Businesses lose opportunities because of this.

Like building a Lego house

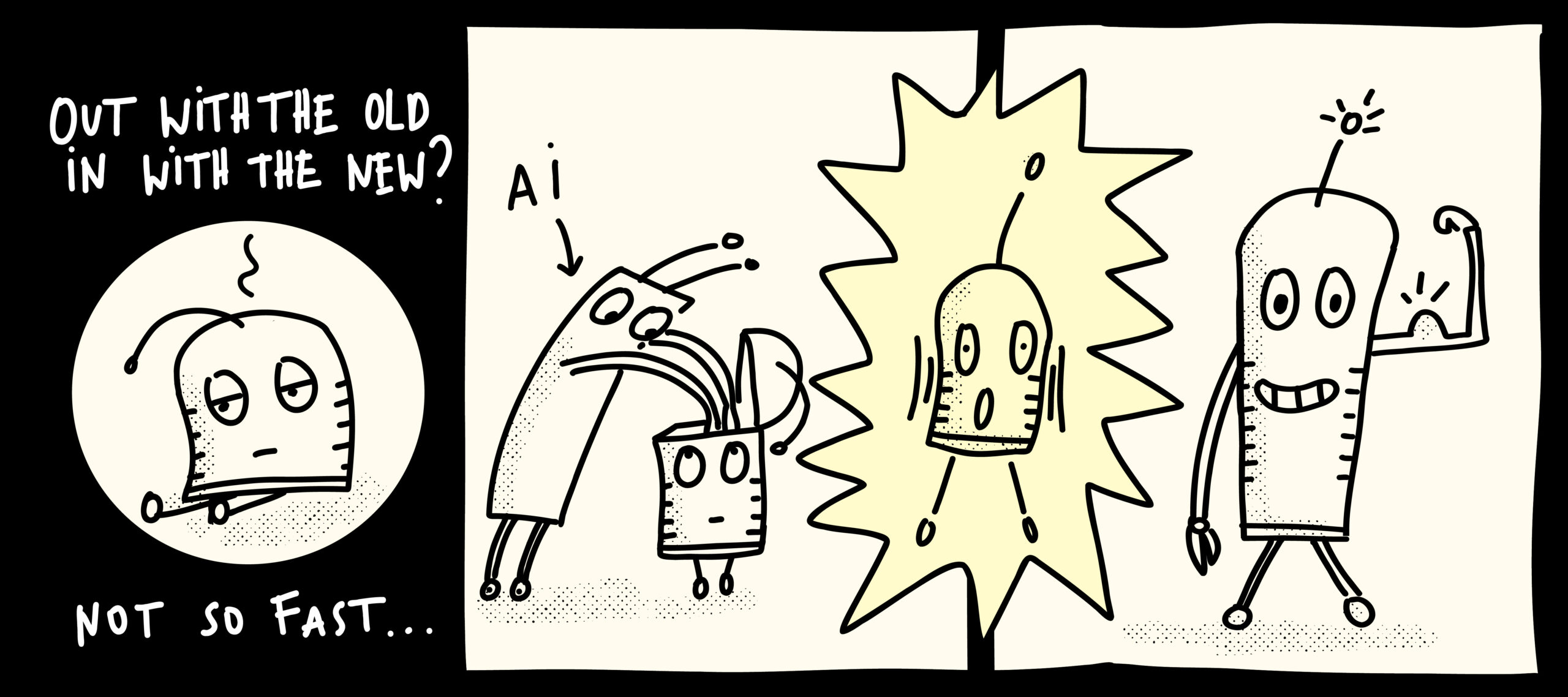

A solution could be to buy a set of new machines. Out with the old, in with the new — right? But who wants to pay that bill? A better solution might be to build new technologies on top of your old machines. AI is the perfect tech tool to add. Look at it as building a house in Lego. Your machine might be a bit old, but it still has all the necessary equipment — like a GPU, ports,… — to connect with your existing infrastructure. In other words: your old machine and new AI will fit perfectly together, like Lego blocks.

So forget new machines, forget giving up on interesting opportunities. Mixing the old with the new is a great way to give your machines a makeover in a simple, low-cost way. Adding AI to your infrastructure will launch your production into a new era, where efficiency and production quality can grow.

Looms, but make it modern

Let’s take a look at what this “Lego machine” is capable of in reality. A manufacturer of cloths that protect tomatoes in a hot climate has a production floor with hundreds of looms — many of them thirty years old. These looms weave one cloth after another all day long, so a production mistake is bound to happen now and then. Without new technology, these mistakes would be missed. The result: lower quality products.

To avoid mistakes and guarantee good quality, our manufacturer could decide to add artificial intelligence to the production process. When cameras detect a flaw, AI now jumps into action. Depending on your preference, AI can do multiple things. For example; it can simply send you data about where/when an error has occurred in the production process. It can stop your machine when it detects a flaw, or it can predict when an error might occur based on previous data.

Ready for another ten years

You get it: no matter how old your machine is, there is a way to make it almost new again. It’s important to keep that in mind because this allows your company to enter this era of fast technology, without making heavy investments in new hardware. With these “Lego blocks” of new technology, your machine works more efficiently and can last another five, ten, or more years.